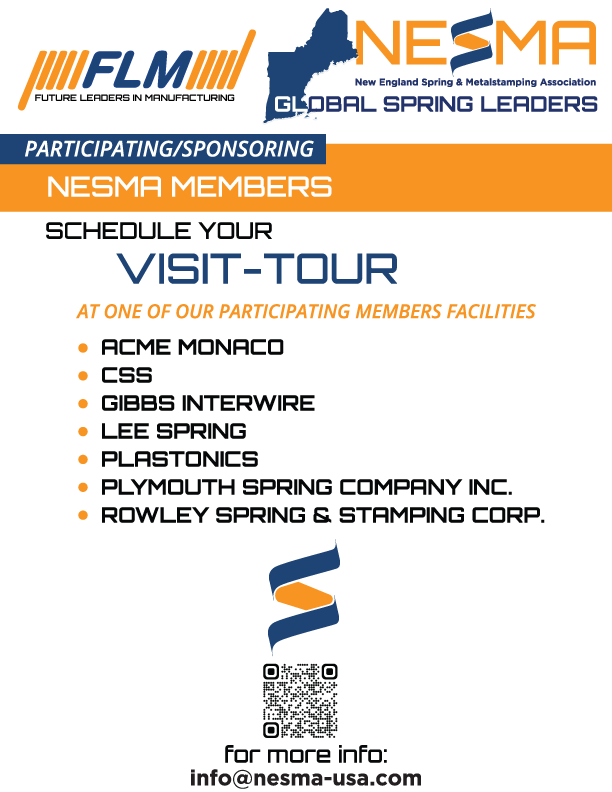

Born in New Britain, it brings me great pride at being the Vice President of Sales at Acme Monaco Corporation, a family owned company that is headquartered in that very city. I’ve had the pleasure of working at the company for 9 years in various roles and have been thankful for the opportunities offered to grow professionally within the company.

After graduating from high school, I attended Providence College to pursue history and finance degrees. The next step of my academic career was spending two years overseas in Germany to achieve a Master’s Degree in International Studies. Those years away at college and studying overseas were a valuable learning experience that I reflect on to this day. Although I did not bring any technical background when I first interviewed at Acme Monaco, the company offers great training as well as hands-on experiences that allowed me to quickly be brought up to speed on our manufacturing capabilities and strengths.

Being a part of a multi-faceted team also allows me the opportunity to consult with the experts at the company in a professional environment that encourages open cross-departmental communication and cooperation that greatly aides in the company’s success. As one of the key employees at the company who is constantly in close communication with clients and colleagues, the confidence in providing them with valuable support while strengthening the relationship is a rewarding aspect of the position.

It is a true pleasure to work hand in hand daily with our customers as a team to see their projects grow from the ground up to reach market success! Most importantly, it gives me great satisfaction to be involved in an essential and respected industry that is known for its clean, reliable, and safe workplace environment while also offering members the opportunity to professionally develop and grow their skills. In my free time, I enjoy honing my culinary skills and staying active by playing ice hockey.

I’d be happy to answer any questions about myself, Acme Monaco as well as the industry – please email me at bschuch@acmemonaco.com.